What factors affect EMG Signal Quality?

High quality EMG signals are essential for the successful execution of research applications.

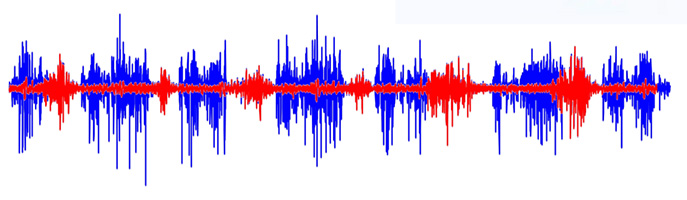

A number of noise sources may contaminate the recording of EMG signals and may not be easily recognized by visual inspection.

These sources can distort the signal and they can lead to errors in the interpretation of the EMG signal for investigating muscle activity.

What are the main sources of noise that affect the quality of the EMG signal?

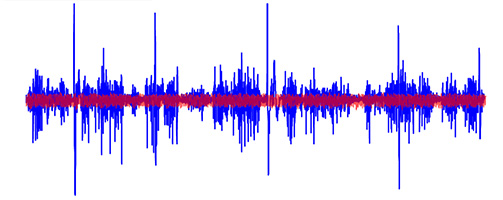

Line interference from power lines (50 or 60 Hz), fluorescent lights and electrical devices originate from the electromagnetic radiation that is pervasive in all environments. While this is generally not a concern with modern technology, line interference may in some cases contaminate EMG recordings.

[/fusion_gallery]The Delsys technology, when used properly, reduces line noise contamination. The real-time Signal Quality Monitor tool that is part of the Delsys EMGworks® Acquisition software provides feedback of the presence of line interference in the EMG recording.

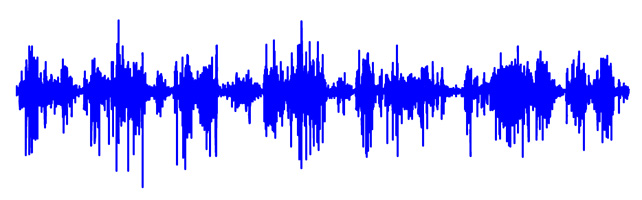

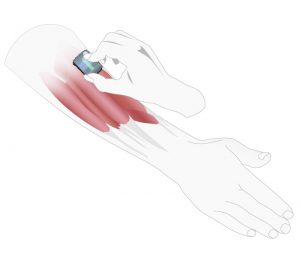

Motion artifact is caused by the relative movement of the sensor with respect to the underlying skin over the muscle of interest.

It can result from: 1) a direct impact to the sensor or to the body, 2) a rapid movement of the body segment to which the sensor is attached, 3) alterations in the chemical balance of the skin-electrode interface due to volumetric changes during shortening and stretching during muscle contraction.

Motion artifact is particularly problematic during dynamic contractions or vigorous activities.

[/fusion_gallery]Delsys sensors are designed with an interface that reduces motion artifact contaminants from the EMG signal.

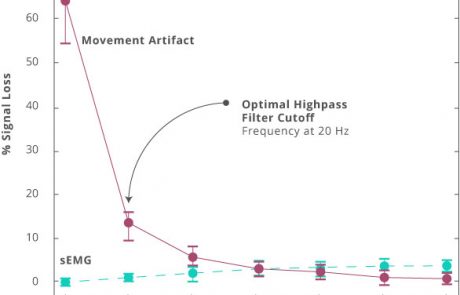

Additionally, Delsys software provides optimal filters to further reduce motion artifact. High-pass filtering the surface EMG signal at 20 Hz reduces motion artifact, whose energy is mostly concentrated at low frequencies, while preserving the frequency content of the EMG signal from the muscle of interest. See our empirical evidence published in Journal of Biomechanics.

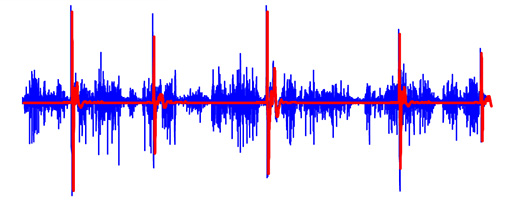

Some portions of the EMG signal may not be from the muscle of interest. Instead, they may result from signals propagated to the sensor from neighbouring muscles. These “cross-talk” signals become superimposed on the EMG signal from the muscle of interest, and their presence distorts the amplitude and timing of the EMG data.

[/fusion_gallery]Delsys sensors are designed with an interface and inter-electrode distance that has been demonstrated through peer-reviewed research to offer the optimal cross-talk suppression while maintaining the EMG signal amplitude. See our empirical evidence published in Journal of Biomechanics.

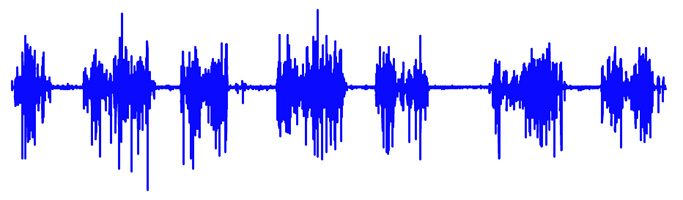

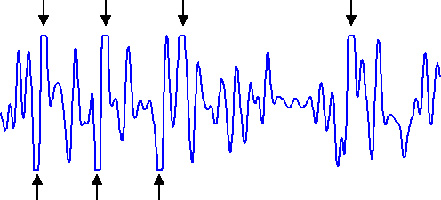

Sensor detachment or excessive EMG signal amplitude may cause saturation, commonly referred to as “clipping”.

[/fusion_gallery]If this occurs, the contact between the sensor and the skin should be secured, the amplifier gain should be reduced if possible, or the location of the sensor on the muscle should be moved to reduce the signal amplitude. The real-time Signal Quality Monitor tool that is part of the Delsys EMGworks® Acquisition software provides an indication of the presence of clipping in the EMG recording.

Physiological noise originates from tissues other than muscles that generate electrical signals, such as EKG signal.

[/fusion_gallery]It can be reduced by properly locating the EMG sensor further away from the source of the noise, if possible. Rotating the sensor so that the electrodes align on equipotential planes, i.e. both electrodes are equidistant from the source, also reduces physiological noise in the EMG signal.

The Delsys sensors can be used as probes prior to final positioning on the skin and can be moved to identify the best position and orientation of the sensor to reduce the influence of physiological noise

How can I ensure good quality EMG signal?

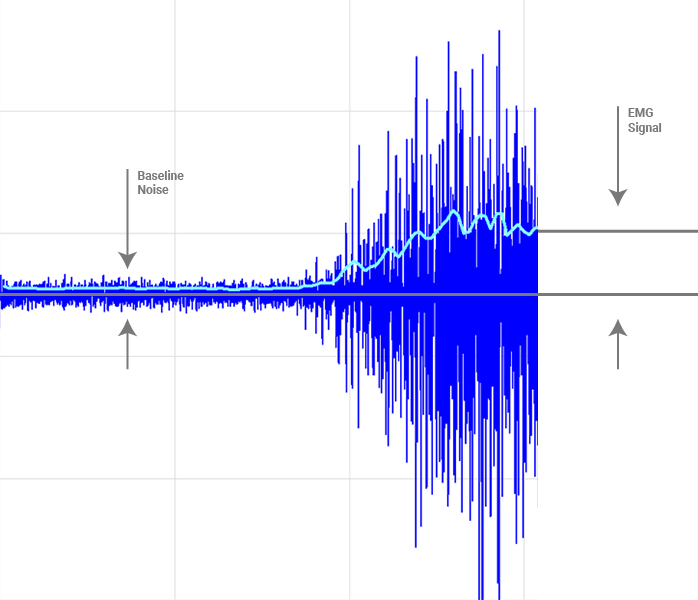

The SNR is the best measure of the quality of the EMG signal. It indicates the ratio of the EMG signal during muscle contraction versus the unwanted electrical signal recorded when the muscle is at rest, i.e. the baseline noise.

The magnitude of the EMG signal depends mainly on the contraction strength, the location and orientation of the sensor on the muscle of interest, the sensor design characteristics, and the amount of fatty tissue between the skin and the muscle. The magnitude of the baseline noise depends mainly on the recording technology and on the quality of the skin-electrode interface

The higher the SNR, the more reliable the discrimination of EMG data from the underlying baseline noise.

The most direct and effective way of achieving high quality EMG signals is to select advanced technology and use it properly.

Delsys provides the most advanced and helpful sensor technology that eliminates much of the unwanted signal noise sources. We also offer the Signal Quality Monitor tool in the Delsys EMGworks® Acquisition software to monitor the quality of the recorded EMG signal in real-time and provide suggestions for improvement.

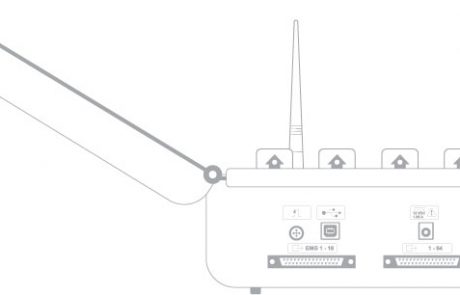

[/fusion_gallery]The Delsys sensor technology incorporates over 20 years of development for high-quality recording of surface EMG signals. Specific designed features of our sensors are identified below which can significantly enhance the reliability, robustness and quality of the EMG signal detection.

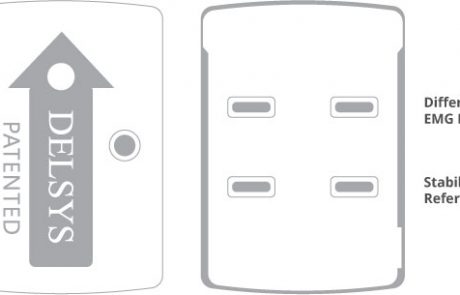

The Trigno wireless sensors contain two stabilizing references in addition to the differential EMG pair. This proprietary design allows the sensor to react instantaneously to disturbances detected on the surface of the skin, reducing the impact of these noise sources on the detected EMG signal quality.

In addition, we have incorporated a 20 Hz high-pass filter that attenuates motion artifact without distorting the physiological EMG signal.

This is documented in one of our recent research publications. See De Luca et al.: Filtering the surface EMG signal: movement artifact and baseline noise contamination in Journal of Biomechanics, 43(8): 1573-1579, 2010.

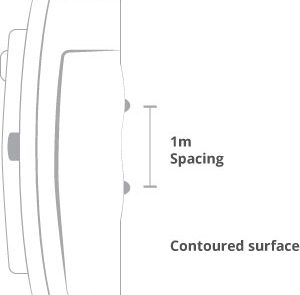

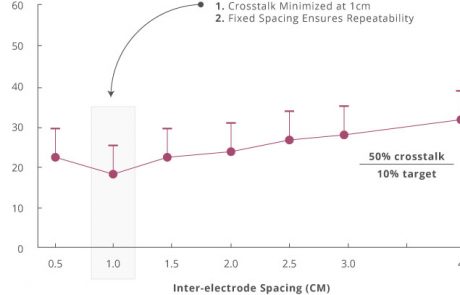

[/fusion_gallery]The signal detection selectivity of a sensor depends on the area and the distance between the detection surfaces. The greater the area and the inter-electrode distance the greater the pick-up area of the sensor and, as a consequence, the greater the amplitude of the detected EMG signal. However, the electrode area and inter-electrode distance cannot be too large in order to minimize the detection of unwanted cross-talk interference from adjacent muscles, including muscles deep to the one of interest. Delsys sensors use a 1 cm inter-electrode spacing, which has been demonstrated through peer-reviewed research to offer the optimal cross-talk suppression while maintaining the EMG signal amplitude.

See De Luca et al.: Inter-electrode spacing of surface EMG sensors: reduction of cross-talk contamination during voluntary contractions in Journal of Biomechanics, 2011.

The inter-electrode spacing is fixed, ensuring repeatability and consistency in experiments. Without fixed spacing, the inter-electrode distance can change with movement, thereby resulting in unwanted alterations to the EMG signal waveform and its frequency content.

The contoured surface of the Delsys sensors is specifically designed to enhance the contact of the sensor bars with the skin and enhance the adhesion of the sensor to the skin.

For details, see Roy et al.: Electro-mechanical stability of surface EMG sensors in Medical & Biological Engineering & Computing, 45: 447-457, 2007 and De Luca et al.: Sweat test for the electromechanical stability of the EMG electrode-skin interface in Proceeding of the International Society for Electromyography and Kinesiology, 2004.

The Delsys EMGworks® Acquisition software includes a real-time Signal Quality Monitor tool to provide feedback of the sensor signal quality. At any time during an experiment, visual warnings are provided if signal quality is compromised. A real time summary display of the signal quality is available that includes feedback of the EMG signal SNR, baseline noise, and line interference. Suggestions for improving signal quality are also provided.

This unique monitoring tool can be used for assistance in locating the sensor on the muscle, or for real-time feedback of signal quality during recordings.

The location of the sensor on the muscle is the single most important factor for good SNR. The placement can maximize the physiological EMG signal and minimize cross-talk interference from neighboring muscles.

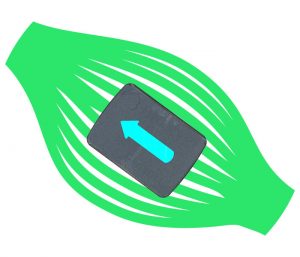

The best location of the sensor on the muscle is generally on the midline of the muscle, far from the tendon origins and the innervation zones, with the sensor arrow parallel to the direction of the muscle fibers.

The best location of the sensor on the muscle is generally on the midline of the muscle, far from the tendon origins and the innervation zones, with the sensor arrow parallel to the direction of the muscle fibers.

In the midline of the muscle, fibers have a bigger diameter and generally yield greater amplitude EMG signals. In contrast, locating the EMG sensor close to the tendon origins reduces the amplitude of the detected EMG signal because, as the muscle fibers approach the tendon, they become thinner and fewer in number. Smaller diameter fibers generate lower amplitude action potentials. Also, in this region the muscle is physically smaller, which makes it difficult to accurately place the sensor and avoid crosstalk interference from adjacent muscles. When possible, innervation zones should be avoided because in these areas the electrical activity propagates in opposite directions along the muscle fibers and can be attenuated.

Muscle fibers generally run longitudinally in a muscle. As a result, the electrical activity propagates predominantly along the length of the muscle. Each Delsys EMG sensor has an arrow on top that should be aligned along the length of the muscle so that the parallel-bar detection sites transect the muscle fibers.

A significant advantage of the Delsys surface EMG sensors is that they can be used as sensor probes on the muscle of interest prior to final placement. As the muscle is contracted, the location of the sensor can be shifted using real-time feedback software to check for signal quality.

For routine applications, the skin surface should be wiped with an alcohol swab. For more extreme conditions, such as in persons with dry skin, hypoallergenic tape can be repeatedly applied and peeled to the skin at the sensor site to remove the outer layer of dead skin.

For routine applications, the skin surface should be wiped with an alcohol swab. For more extreme conditions, such as in persons with dry skin, hypoallergenic tape can be repeatedly applied and peeled to the skin at the sensor site to remove the outer layer of dead skin.

The sensor should be firmly attached to the skin using the Delsys double-sided adhesives to ensure good contact between the electrodes and the skin. The use of gel electrolyte, commonly used in other EMG sensors, is not recommended. Delsys sensors are designed to be used as “dry electrodes”.

The sensor should be firmly attached to the skin using the Delsys double-sided adhesives to ensure good contact between the electrodes and the skin. The use of gel electrolyte, commonly used in other EMG sensors, is not recommended. Delsys sensors are designed to be used as “dry electrodes”.

Summary of Recommendations for Recording of High-Quality EMG Signal

| EMG Sensor Technology use advanced high-quality sensor technology with small (1 cm or less), and possibly fixed, inter-electrode spacing. |

| Reference Electrode ensure the reference electrode, if separate from the EMG sensor, is connected to the instrumentation and to the skin of the subject. |

| Sampling Rate ensure that the surface EMG signal is sampled at least at 1000 Hz. |

| Amplifier Gain a gain of 1000 is usually appropriate for surface EMG signals. Ensure that no clipping is present in the signal. If this occurs, check that the EMG sensor and reference electrode are adequately attached and connected. Reduce the gain or reposition the EMG sensor to reduce the signal level. |

| Filtering a Butterworth filter with corner frequencies of 20-450 Hz and a slope of 12 dB/oct is recommended for general use in surface EMG recording. |

| Environment Ensure that there is no instrumentation or electrical connection introducing line interference in the recording. |

| Skin Preparation remove excessive hair. Clean the skin with alcohol to improve electrical contact with the sensor. If necessary, peel off the layer of dead skin with hypo-allergenic tape. |

| Sensor Placement place the EMG sensor in the in the middle of the muscle belly, away from innervation zones and tendon origins and as far as possible from sources of physiological noise, with the electrodes aligned parallel to the muscles fibres. |

| Sensor Attachment ensure good contact between the electrodes and the skin. |